Project Description

New Steel Lift Shaft Structure and Other Builders Works

CBES were contracted to carry out all enabling works to include lift removal. It was found after the lift was removed that the landing entrance wall had been cut away. This meant the remaining 3 walls were not attached to the building structure and could not take the loads imposed by the new lifts.

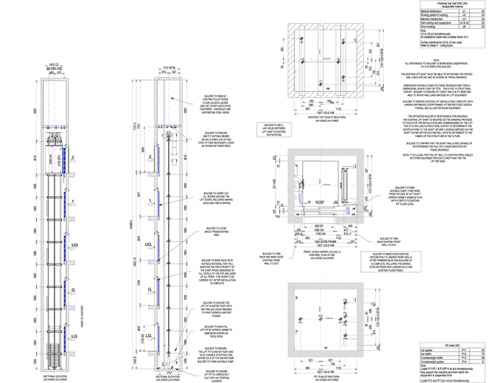

CBES were then contracted to design and fabricate a new steel shaft structure. The structure had to be designed, fabricated, and then filled with only 5mm tolerance.

Before the steel frame was fitted the internal shaft walls had to be carefully removed. An added problem was that this meant if the wind blew above 40mph the single outside skin of brickwork could collapse. A two-week window of settled weather was needed before we could demolish the internal walls.

The internal walls were carefully removed, and the bespoke steel frame were filled in 10 days. Notably due to unsquared walls the steel work had to be plumbed in a space with a tolerance of only 3mm.

The steel structural frame was not only designed to take the lift loads it was also built with steel fixing plates to pick up the shaft guide rails and lift motors and safety equipment.

Once the steel frame was installed into the shaft it was tied into the building structure and existing external shaft walls and internal floor levels.